Before I went to Lorenz Ganter in Ismaning for the first time, I told Dieter Ganter that I wanted to bring a coupon for hunter linen from Leichtfried Loden. I told him my idea for a suit in traditional costume style: the jacket should be cut like the apple-green linen jacket I ordered from Lorenz Ganter via Campe & Ohff. Plus, of course, pants made from the same fabric. So I asked whether Ganter also makes pants. Dieter Ganter’s answer was so reserved that I got the impression that he doesn’t like making pants: “Yes, we do make them. But we only have two basic shapes”. I therefore said that I could also have the trousers tailored by another tailor. But Dieter Ganter suggested that I should take a look at his trouser models on my next visit.

During the tour, I noticed the striped cut pants that are available off the rack at Ganter. They are cut high, have a back strap and pleats. The buttons for the suspenders are sewn onto the outside of the waistband, as was customary until the 1920s. After the tour, when we went to the store at the front of the company building to look at my suit, I was sure that I would have my trousers made by Ganter. But first we turned our attention to the jacket.

My first linen jacket from Ganter was based on a size. 50. 48 was now recommended to me. I tried on a sample and was 95 percent convinced that these greetings are better. It was missing 5 percent because the pattern piece had a back strap and therefore fell slightly differently. But I finally agreed to the size suggestion. I wanted to do without the shoulder pads again. The sleeve length was measured on the piece and adjusted to my figure. My arms are longer than usual for this size and the right arm is 0.5 cm longer than the left. Apart from that, there was nothing to change in the cut. Dieter Ganter merely noted that I was once again dispensing with the shoulder pads. The cut is slightly modified for this, but Dieter Ganter does this automatically when he designs it.

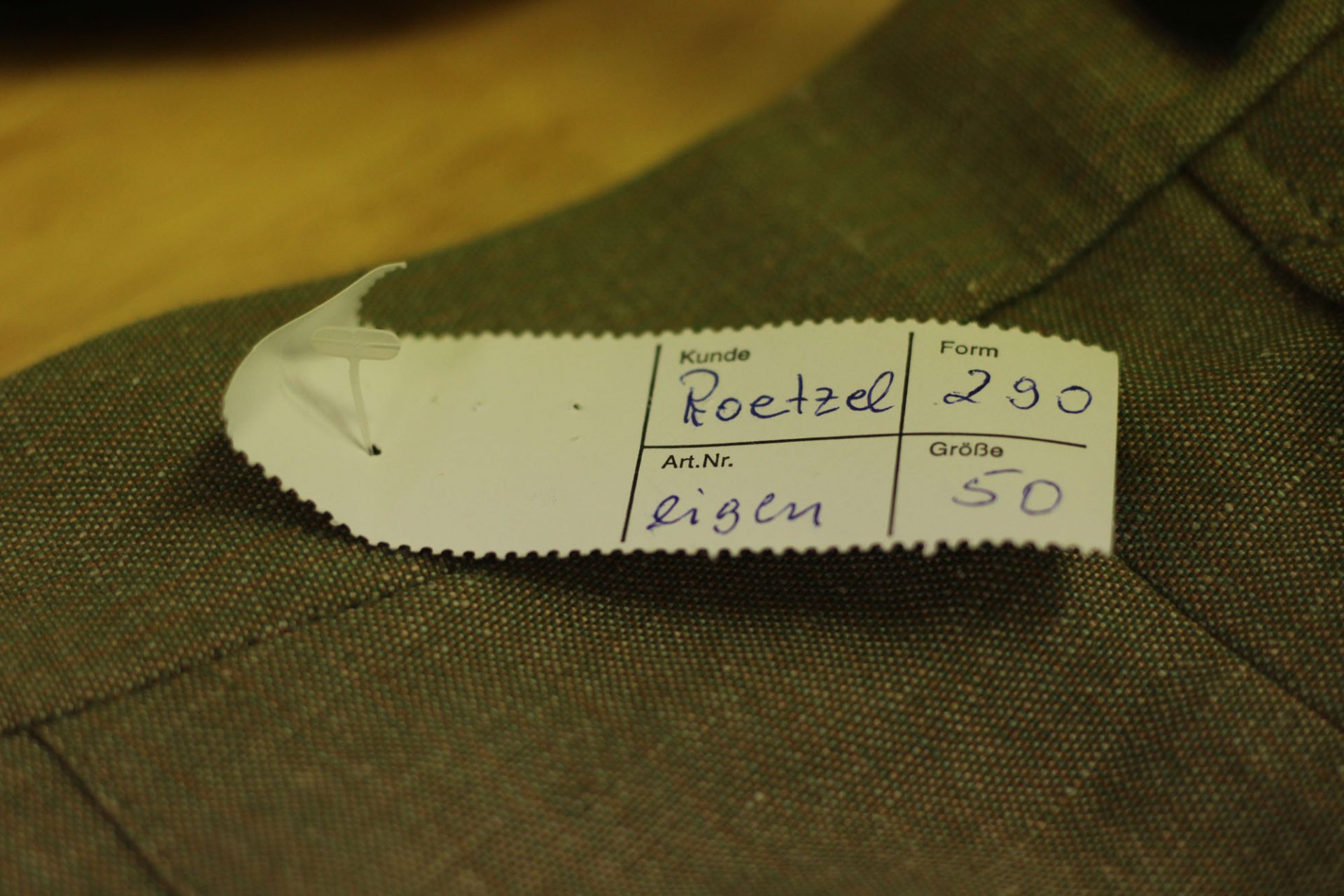

Now we turned our attention to the trousers. Dieter Ganter brought me a sample in size. 48, but it was a little too tight and too close to the buttocks. The 48 was the correct size, but it was too tight for me. So I tried the 50 and it fitted exactly as I imagined. Dieter Ganter was a little surprised, but I was not. I usually choose pants that are traditionally cut one size larger, then they usually fit better. I left out the back pockets and the leg pocket for a knife. It is common for striped couture pants to be worn with traditional costumes and I briefly considered it, but then decided against it. The total length has not yet been measured, as we agreed that the pants should be delivered unhemmed. We ended up talking about a detail that was important to me: I wanted the pleats to be “forward pleats”, i.e. pleated inwards. Dieter Ganter had never made them like this before, but was happy to comply with my request.

In the end, I chose the green felt for the collar and the lining for the jacket. I went for a slightly lighter, fresher shade of green. I had golden yellow satin in mind for the lining and we quickly found the right quality in the fabric sample bundle. Dieter Ganter wanted to find the matching striped sleeve lining. I chose staghorn for the buttons. Dieter Ganter recommended a decorative strip of green felt for the cuffs, onto which the two sleeve buttons are sewn. I hesitated at first because the cuffs of my first Ganter jacket didn’t have this decoration, but then I followed the recommendation. Not least because you can remove the strip again if I don’t like it.

We agreed that I would get a message when the suit was ready. But I wanted to arrange it so that I could pick up the suit myself. It was important to me that we look at it together and determine the length of the pants. The order was placed on January 19, 2024, and I was back in Ismaning on March 13, 2024 to pick up the suit. Dieter Ganter documented the production of the suit in great detail in photographs and a video, which he kindly made available to us. So we can show all stages of production, even though we weren’t there.

When I visited in January there was still snow, but in mid-March it was mild and sunny. I traveled directly from Munich Central Station to Ismaning in the afternoon and arrived there at 3 pm. The suit was already hanging ready for me in the store and I liked it even better than in the photos I had received in advance. Hunter’s linen is a fabric that has several shades of color and is similar to solaro. With a new suit, it is as smooth as it will ever be after the first wear. Unless you re-iron it. However, hunter linen should not be completely smooth, it looks much more charming when it has been worn a little. Incidentally, this fabric is not pure linen, but rather a blend of cotton and linen. This means it creases a little less.

I took the suit into the changing room and put on the pants first. We buttoned up the suspenders and adjusted them to the right length. Then Dieter Ganter adjusted the back belt and now I could look at the pants in the mirror. They fit very well – a little fuller in the leg and the foot width was not too tight. The crease runs vertically across the middle of the knee. The inward pleat was very well done. There was no need to alter the cut, it just had to be placed the other way around after cutting. Dieter Ganter now measured the length of the trouser legs using his own method with the help of a kind of template and noted the measurement for the seamstress. I was wearing chukka boots that day, which I wouldn’t wear with these pants. Since Dieter Ganter measured the length of the pants and didn’t mark them out, it didn’t matter. I stood there on stockings, he took the floor as the end point for the measurement. The floor replaces the sole of the shoe on which you stand. The decisive factor for the measurement is that the trousers reach approximately to the middle of the heel at the back and fold in slightly at the front on the instep of the stockinged foot.

Then Dieter Ganter helped me into my jacket. It also fitted very well. My uncertainty about the size turned out to be unfounded, I was glad that I had followed Dieter Ganter’s recommendation. The overall length was perfect and the shoulders look natural without padding. I find the slightly rounded shape elegant and at the same time in keeping with the rural style of the suit. The box pleat at the back provides plenty of freedom of movement, which makes the suit extremely comfortable, especially in combination with the suspenders on the legs. The sleeves fit very well with no creases at the back. The length was perfect, the shirt cuff sticks out just as far as I had imagined. Given the fit of the trousers and jacket and the fact that the cut of the jacket and trousers has not been altered, apart from the length of the sleeves, the result is very convincing. When I said this, Dieter Ganter modestly refused and praised my figure in return, saying it was very simple. That may be the case, but there have already been a number of pieces made to measure for this figure, either industrially or by hand, which did not fit as well as this suit. However, there are certainly customers whose bodies are a greater challenge for Dieter Ganter.

I changed quickly so that my pants could be shortened. One employee had stayed longer and immediately got to work. I took some photos of her marking the length with tailor’s circles, cutting off the excess fabric, sewing on the bump tape, turning the pants inside out and finally sewing them on. Dieter Ganter had asked me beforehand whether the hem should be like a pair of suit trousers or sporty like a pair of chinos. I chose the more formal version because it seemed more suitable for this cut of pants. After the alteration, I put the pants on again and the measured length turned out to be correct: as predicted, the pants fall straight down and crease very slightly on the instep.

As with the first order, I am very satisfied with this suit overall. Individual orders in ready-made sizes with only minor changes to length and circumference measurements are a good alternative to made-to-measure clothing. The customer can already see what to expect when trying on the sample piece. The provider does not have to “reinvent the wheel” when editing, he can limit himself to adjustments in order to anticipate changes. For example, the overall length, the length of the sleeves or the waist and leg width of the pants – it is difficult to draw a comparison with bespoke tailoring. Lorenz Ganter has no intention of competing with this. A bespoke tailor will carry out many of the work steps that are done by machine at Ganter by hand. This results in a better fit in the jacket, but the differences in the pants are mainly cosmetic. I sew clothes by hand, but I am very satisfied with the quality level of Lorenz Ganter. I don’t miss hand-sewn buttonholes so much that I would go to the extra effort. Perhaps it would be possible, for example, to have the items delivered without buttonholes and then have hand buttonholes added by a tailor. In my opinion, however, that would be inappropriate. Good clothing should not pretend to be something it is not. Lorenz Ganter’s suit is excellent as it is. I think the pictures illustrate this well. Otherwise, it is up to you to visit the workshop in Ismaning and try it yourself. I can definitely recommend it. If you would like to make an appointment, please email Dieter Ganter at mail@lorenz-ganter.de.