In the 19th century, Milan was part of a flourishing Italian umbrella industry with around 100 companies throughout the country. Novara was considered the traditional center of the industry, but numerous manufacturers were also based in the Lombardy metropolis. Thirty years ago there were ten, but today there is only the Fabbrica Ombrelli Magli. Since 2019, it has been managed by Francesco Maglia, the nephew of Francesco “Chino” Maglia, in the 6th generation.

His uncle was the face of the brand for decades. The tall Milanese, whose beard is vaguely reminiscent of the composer Giuseppe Verdi, now only looks after selected customers. But his nephew Francesco has umbrella-making in his blood too, having started learning his family’s trade 30 years ago at the age of twelve.

Sustainability is an important focus for Francesco Maglia, which is why he wants to make his umbrellas even more durable. To achieve this, he relies on fabrics that are woven on Lake Como, i.e. in the region and not in Asia. The carefully selected woods for the sticks and handles are sourced exclusively from open-air woods in Europe. And the metal parts are precisely manufactured to ensure smooth operation, a long service life and the attractive appearance of the shades down to the smallest detail.

The materials are only one side, the other is the manual work. Both together make the difference to cheap umbrellas from Chinese mass production. However, they are no real competition for the umbrellas from Milan. Competitors are high-quality umbrellas from Europe, e.g. Brigg in England, Pasotti in Naples or Doppler in Austria. Maglia fights against these competitors above all with the high degree of craftsmanship and the variety and originality of the fabric selection. And of course, the UK’s main competitor, which towers above all its rivals in terms of prestige, has become even more expensive as a result of Britain’s exit from the EU.

The production of an umbrella at Maglia is time-consuming. But even if the Manufakur is due to close for the August vacations, the boss cannot speed up the processes. First, the upholstery fabric is selected. The selection is extensive and includes various colors and designs in addition to the traditional black: pinstripes, glenchecks, tartans, houndstooth, herringbone in cotton, polyester and polyamide blends. Then comes the cutting: An umbrella maker calmly unrolls the fabric, transfers the pattern onto it and then cuts out each segment of the cover individually.

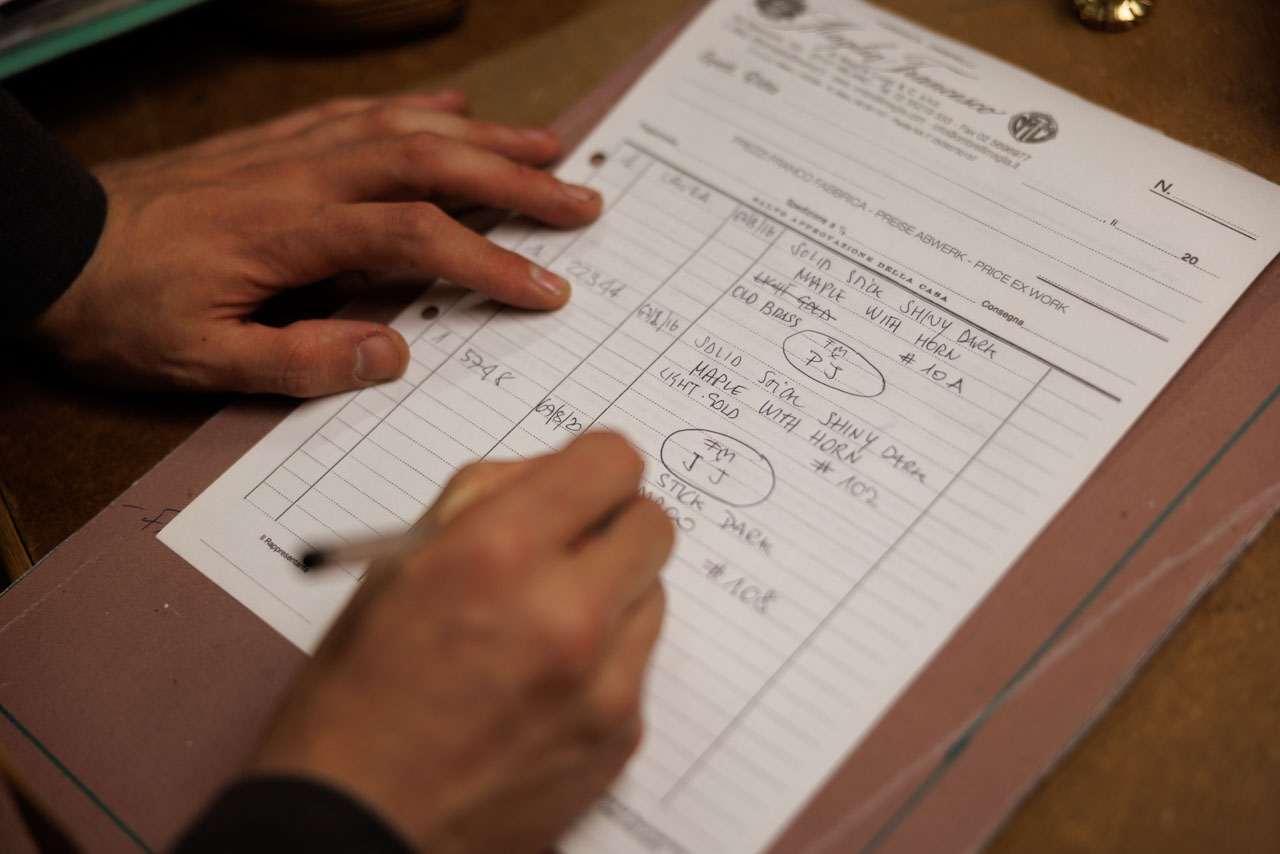

Meanwhile, a worker collects the necessary sticks. They are stored separately in a room with optimum humidity and temperature. The stockroom is the manufactory’s treasure trove. The wood comes from Italy and Germany. Maple, walnut and apple from Bad Sooden-Allendorf in Hesse, for example. The rods are now mounted on the poles and the handles are glued. A few meters away sits the colleague who joins the cover to the frame with a needle and thread. There are a total of 70 work steps between cutting and final inspection, and the leftover pieces of fabric that are too small to be made into umbrellas are now turned into bags and hats. Another idea from the new boss.

Two other innovations that he has introduced are more significant for the overall result: The online store, which was opened in 2020. And the Bespoke service for end consumers. Customers from all over the world now come to the factory every day, and umbrella fans ordered Bespoke rain canopies during our visit. Visitors literally come from all over the world, explains Francesco Maglia; they are at home in over 40 countries. And walk around there with the umbrellas from Milan. A visible statement of style and sustainability. Not only in the rain, because Maglia also makes parasols.