The Ludwig Reiter shoe manufactory produces ready-made shoes, so there is no custom-made production in the sense that shoes are built on individualized lasts. However, it is possible to have a ready-to-wear shoe made individually. In England and the USA, this option is called “made to order”. At Ludwig Reiter it is called a private production. I interpret this word to mean that a shoe is made to order by a private individual. In contrast to the special orders that retailers place for their business. It is common practice for a retailer to have models from the Ludwig Reiter range made from leather types or with special details for his store, provided a certain minimum quantity is ordered. Some also have their own embossing stamp made, with which the name of the retailer, a brand or a designer is noted in the shoe alongside the Ludwig Reiter brand name. I have seen several such stamps in the manufactory, e.g. for the shoes made for the German ready-to-wear company Windsor. I don’t know whether you can have your name embossed on the lining as a private individual. And I must also confess that I didn’t ask about it.

Anyone wishing to order the custom-made shoes must visit one of the Ludwig Reiter shoe stores. So it doesn’t work in shoe stores that stock Ludwig Reiter. And not online either. The addresses of the Ludwig Reiter stores can be found on the Austrian manufacturer’s website. I ordered the private production at the factory outlet at Gut Süßenbrunn (in Austria it’s actually called a factory outlet, not a factory outlet) at the end of the tour of the manufactory. I enjoyed the special privilege of having Till Reiter personally at my side. The factory outlet is open from Monday to Friday, the exact times can also be found on the website. The main purpose of this store is to sell individual pairs and special models to men and women, but as in every Ludwig Reiter store, you can also configure your own custom-made shoes there. This verb, which is often used in connection with the purchase of cars, applies well to the ordering process.

The first step is usually to find the right slats in the right length and width. Unless the shape of the last and its size are known. Which is certainly the case for many customers. Since I last bought a pair of Ludwig Reiter shoes in 1990 or 1992, it was absolutely necessary to find out the last shape and size first. For men, there are several lasts to choose from for welted models, e.g. English, Viennese, Salzburg, Tuscan, Hungarian. I like the latter strip best. It is not as elongated and narrow, the toe cap, which is somewhat reminiscent of the shape of a ship’s bow, offers plenty of room for the toes. I’ve always liked this shape, but only started wearing shoes in this shape a few years ago. So it was clear to me that it should be this last.

When it came to the model, I had my heart set on the Norwegian; for me, despite the Scandinavian-sounding name, it is the epitome of the Viennese shoe. I don’t know of any city where I see so many men in Norwegian shoes, especially in fall and winter. Mostly made of brown or black Scotchgrain leather, often in wine red, more rarely in green or blue. For the last shape, it should be the “Hungarian”. It is slightly shorter, the toe cap is higher and the profile is reminiscent of a ship’s bow. The shape makes the shoe appear slightly shorter. The Norwegian is also available on slimmer lasts, e.g. the Salzburger, but I wanted to try the other last shape. I guessed the size to be 42, but the factory outlet had the model in black scotchgrain in F width. For about two years now, I have preferred a slightly wider last, so usually no longer F, but rather G. With some manufacturers, even H. In this respect, I was curious to see how F would fit. It turned out to be very good and I also liked the proportions. On the right foot, the shoe pressed a little on the little toe, but I assumed this was due to the stiffness of the Scotchgrain leather. Till Reiter agreed with me in this assessment. To be on the safe side, I also wanted to test the last in the wider G width.

Being Norwegian, it wasn’t in stock in this width size at the factory outlet, so I tried a brogue in the fit I wanted. It turned out to be a little too wide and also too voluminous. So I stuck with size 42 in F. However, Till Reiter recommended lowering the instep a little on the left shoe. My left foot is a few millimeters shorter and a touch thinner at the instep than my right foot. This difference is not visible on the stockinged feet, but I notice that the right shoe always fits a little tighter and also because the lacing on the right is a little wider. The so-called instep drop takes away a little width at the instep by not closing the lacing completely before putting the shoe on. This pulls the upper a little further around the last. If you lace up the finished shoe properly on the foot, it will fit more snugly on the slimmer foot. I had never heard of this method before, but I was keen to try it.

I briefly considered green suede for the leather. But then I listened to my inner voice, which reminded me that I already own a pair of shoes in this type of leather. And since I don’t wear green shoes that often, another green pair wouldn’t be used too often. So I opted for what I wear most often: brown suede. There is a thick bundle of leather samples available for the private production, which actually offers a comprehensive selection. As the factory outlet is only a few steps away from the leather warehouse, I wanted to take a look at the leather pieces on the shelves. Together with Till Reiter, I went to the warehouse and after a short search I came across a brown suede leather called “Velour marron” on one of the shelves. It reminded me of the English “Tobacco calf suede”, but it was a little lighter in color and also more velvety to the touch.

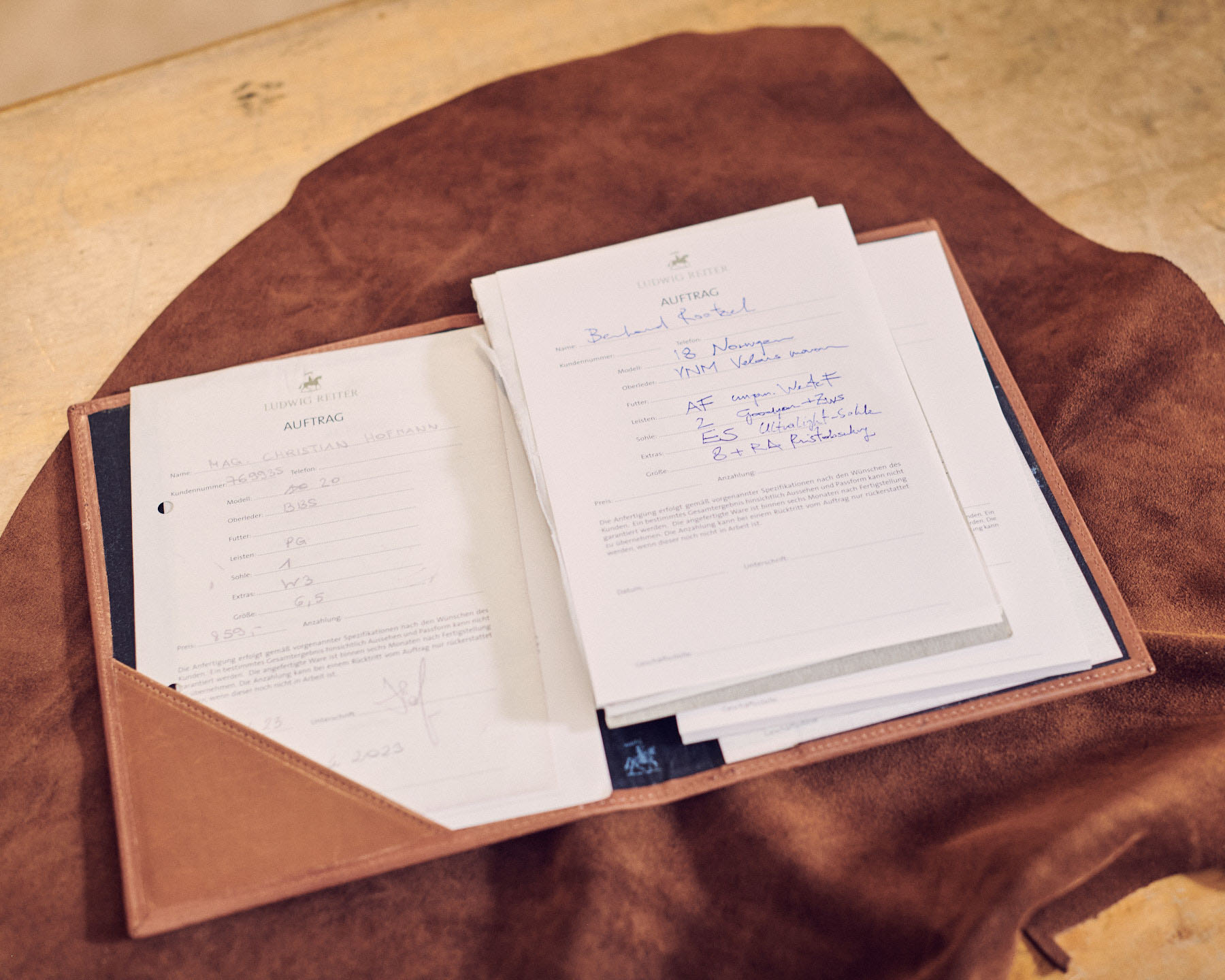

Back at the factory outlet, we still had to choose the sole. There are also several options to choose from. I wanted a weatherproof, soft and lightweight sole. The normal Vibram tread sole is relatively heavy, which is why Till Reiter recommended the “Ultralight sole”. It is made of black rubber, the profile is slightly less deep and it is really very light. I briefly considered whether to order this sole without tread, but then stuck with my first choice. It seemed more suited to the Norwegian’s rural character. In the end, Till Reiter summarized the order on an order form: “Model 18, Norwegian. Upper leather VNM Velours marron, last AF ungar. Width F. ES Ultralight sole. 8 + instep drop.” I received a copy of the order as confirmation and as a reminder. I’m told that the surcharge for a custom-made model like the Norwegian is “from 100 euros”. More elaborate requests increase the price of the surcharge. In the case of the Norwegian, I consider the surcharge to be moderate, because overall the price of a Norwegian from Ludwig Reiter is not in the absolute top range.

The delivery time for custom-made products is stated as “a few weeks” on the Ludwig Reiter website. I visited the manufactory at the end of October and the shoes should be ready before Christmas. They were delivered on December 11, i.e. at the announced time. They came in the dark blue Ludwig Reiter box, together with dark blue cloth shoe bags. When I took the shoes out, I immediately noticed how light they were. Shoes with Vibram tread soles are significantly heavier. As a finished shoe, the leather looked a little lighter than I remembered. The workmanship is very careful and clean. When I put the shoes on, they fit very well. As expected, the leather was soft and adapted well to the foot. The lowering of the instep also worked, the shoe sat nicely close to the instep on the narrower foot. The Ultralight sole proved to be very soft underfoot. That same day, I started to register the shoes at home. After a morning at home, I wore the shoes outside for half a day. This was not a risk, as the upper leather fitted very well straight away and did not pinch anywhere. Before the first trip outdoors, I treated the shoes thoroughly with waterproofing spray. I then wore the shoes for a whole day and had no problems. The private production was worth it for me. Firstly, because I chose a leather that is not in the collection. Secondly, because I was able to optimize the fit by lowering the instep on the left foot. This improvement is not so serious that I wouldn’t buy a shoe off the rack in size 42 F in the future on my preferred last. However, I would generally opt for a custom-made product again, as I usually have a special request. So I already have a model in mind that I could imagine for the summer. And what I have in mind is not to be found in the collection. But that’s another story.